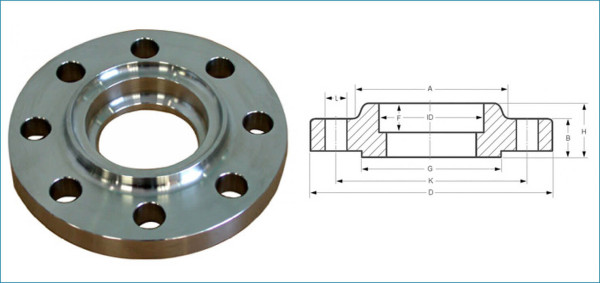

Socketweld Flanges

Copper Nickel Socket weld Flanges Supplier, Socketweld Flanges Stockist, Stainless Steel Socket weld Flange, Alloy Steel Socket weld Flange, Copper Nickel Socket weld Flanges Exporter.

An ISO 9001:2008 manufacturer and exporter of Socket Weld Flanges, Metal Tubes India is a long time and competent company that holds a 40-year-old experience in delivering standard, proficient flanges to process industries, suitable enough to use with instrumentation and pneumatic applications.

These flanges are counter-bored i.e. the bore of the flange and pipe, both are same, thereby providing a good flow of the product through the pipe. Initially used for small-sized high pressure pipes, they are now used in high pressure systems too. A demerit of socket weld flange is the gap created between the pipe and flange during the welding process, which may lead to corrosion of the metal.

Duplex Steel SWRF Raised Face Flanges Dealer, Alloy Steel SWRF Flanges, Steel SWRF Flanges Wholesaler, Hastelloy SWRF Flanges, Inconel Socket weld Flange, Incoloy SWRF Flanges Stockist.

Flanges - ANSI B16.47 SWRF Flanges, ANSI B16.5 Socket weld Flange, SWRF Flanges Distributor, Alloy 20 Socket weld Flanges, Incoloy Socket weld Raised Face Flanges, Socket weld Flanges Stockist, Socket weld Raised

Face Flanges, Stainless Steel SWRF Flanges Distributor, Copro Nickel SWRF Flanges Suppliers, Duplex Steel UNS S31803 Socket weld Flange, Duplex Steel UNS S32205 SWRF Flanges, Super Duplex UNS S32750 SWRF

Flanges, Super Duplex UNS S32950 Socket weld Flanges, Cu-Ni 90/10 (C70600) Socket weld Flanges Distributor

40 years of Committed Experience in Socket Weld Flanges & Other Products As Per ANSI B16.5,

ANSI B16.47

Metal Tubes (India) Supplier & Exporter Flanges In World Wide

Carbon Steel Socket Weld Flange

Alloy Steel Socket Weld Flanges

Stainless Steel Socket Weld Flanges

Manufacturer of Global Metals India

TYPE : Slip on, Weldneck, Blind, Socket Weld, Threaded, Lap joint (Stubend) Ring Joint,

DIMENSIONS : As per ANSI B 16.5 for forged steel flange.

SIZE : 1/2”, 3/4”, 1”, 1 1/4: 1 1/2”

MATERIAL : As per ASTM A 105 (High Temperature Service) as per ASTM A181 (General Service ) Carbon Steel Grade ASTM A 182 for High

TEMPERATURE SERVICE : For SS 304 & SS 316

Threaded Reducing & Orifice Pressure Rating as per BS 10 : 1962

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports